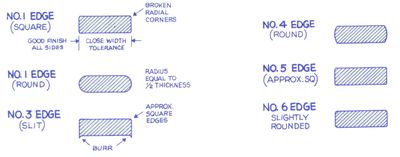

EDGES

Mokes Steel can supply stainless and cold rolled strip with any one of six standard edges. These edges are specified by No. 1, 3, 4, 5, and 6. The No. 3 edge is included in the base price; extra is charged for the other edges because of the cost to manufacture. Minimums will apply depending on the edge required.

No. 1 Edge

This is the best edge developed. It can be either round or square, but in either case, the finish of this edge must be equal to the surface finish. The edge is produced by first slitting the strip at or near finished thickness. Then this strip is passed through the file board to remove burr and to shape the edge. Another very common method of making No. 1 edge is that of edge rolling the slit strip with the shaped edge rolls or by using a Turk's head.

There are two types of edges included in the No 1 edge classification: the standard square and the full round edge.

No. 3 Edge

A slit edge is produced by an edge trimming operation. This is performed by passing the strip through the slitter. The No. 3 edge is by far the most prevalent edge found on strip product.

No. 4 Edge

A finished round edge is produced by edge rolling the strip during cold rolling and may be manufactured only in those widths and gauges at which the strip will not buckle during the edging process. It is used when an approximately round, but not highly finished edge is desired.

No. 5 Edge

This is a square type of edge. It is a No. 3 edge improved by running the strip through edge rollers for removal of burrs. This edge is free from any slitting burr.

No. 6 Edge

This edge is the same as a No. 4 edge except that it is square rather than round. As with the No. 4 edge, the No. 6 edge is not suitable for electroplating, but is good for painted products.

Copyright © 2019 Mokes Steel, Inc. - All Rights Reserved.