COLD ROLLED CARBON STEEL STRIP

The temper or the state of hardness or ductility is the measure of strip's ability to be shaped or formed as desired. Cold Rolled Strip is supplied in five standard tempers, known as 1, 2, 3, 4, or 5.

No 1. Temper (full hard)

This is the hardest temper which can be produced by cold rolling a low carbon strip. No. 1 temper results in a very stiff springy strip, recommended for flat applications only.

Rockwell B 90 minimum if .069 or thinner, B 84 minimum if .070 or heavier, with .25% maximum carbon

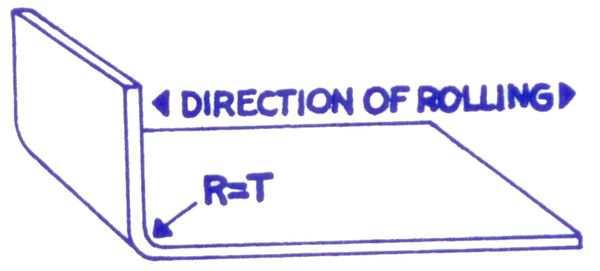

No 2. Temper (half hard)

No. 2 temper produces a moderately stiff strip intendend for limited bending. Strip of this temper can be bent 90 degrees across the direction of rolling, around a radius equal to the strip thickness. It is produced by giving the annealed strip considerably less reduction than that which produces a No. 1 temper. For this reason, it becomes more difficult to produce a good quality finish especially if the strip is of a heavy gauge.

Rockwell B 70 minimum - B 75 maximum*, with a .25% maximum carbon

* Within the Rockwell "B" limits of No. 2 and No. 3 tempers, any 15 point Rockwell range is considered standard. .

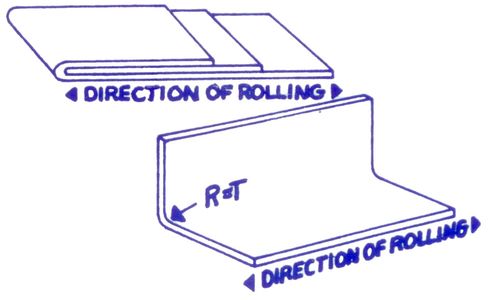

No 3. Temper (quarter hard)

This temper yields a medium-soft strip intended for limited forming, bending and easy drawing. A strip of No. 3 temper can withstand a 180 degree bend across the grain over one thickness of the strip and a 90 degree bend with the grain around a radius equal to the thickness. The No. 3 temper is popular because it combines rigidty with a good deal of ductility.

Rockwell B 60 minimum - B 75 maximum*, with .25% maximum carbon

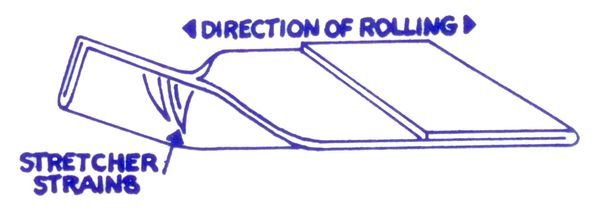

No 4. Temper (skin rolled or pinched)

A very large amount of Cold Rolled Strip is given this temper because it is so well adapted to formation work. It is a soft ductile strip for drawing applications where surface disturbances, such as stretcher staines, are objectionable. No 4 temper strip can be bent flat upon itself in any direction.

Rockwell B 65 maximum (no minimum), with .15% maximum carbon

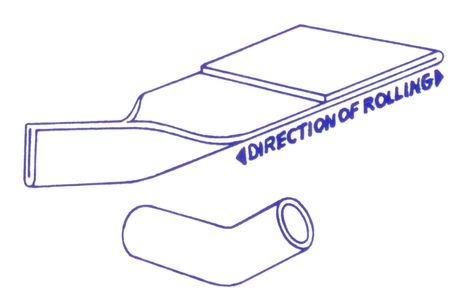

No 5. Temper (dead soft)

This is the softest of the standard strip tempers. Its processing does not include any cold working after annealing at finished size. This fact explains why No. % temper strip is very desirable for all purposes where difficult drawing or bending is required. No 5 temper strip can be bent flat upon itself in any direction and is intended for deep drawing applications where surface disturbances are not objectionable.

Rockwell B 55 maximum (no minimum), with .15% maximum carbon

Copyright © 2019 Mokes Steel, Inc. - All Rights Reserved.