Our Process

1. Inventory

We inventory over 1 million pounds of steel in a wide range of gauges allowing us to select the proper material for the manufacturing of your order.

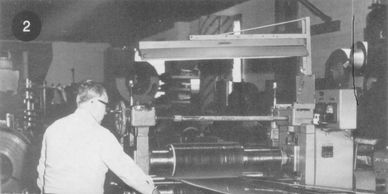

2. 36" Yoder Slitter

Our heavy gauge slitter can handle coils up to 36 inches in width and weighing as much as 12,500 pounds. It can slit gauges ranging from .010 to .125 in thickness to widths as narrow as .500.

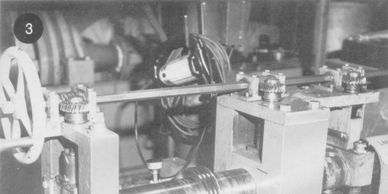

3. 14" CMP custom light gauge slitter

This machine can accomodate coils up to 14 inches wide. It will slit gauges as light as .002 to widths as narrow as .093.

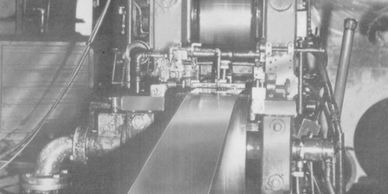

4. 8" Steckel cold roll tempering mill

Very few service centers have a cold roll termpering mill. Our mill can produce close tolerance tempered stainless and low carbon steel in widths up to 8 inches wide. We can produce any quantity to your exact specification.

5. 36" Niagara McKay sheeting line

Flat strips with a width tolerance of +/-.005 and a length tolerance ot +.125/-.000 are produced on our sheeting line. This piece of equipment gives us a great deal of versatility. It can handle coils up to 10,000 pounds, 36" wide, to as narrow as 3/8" It can cut lengths from 24 inches to 240 inches.

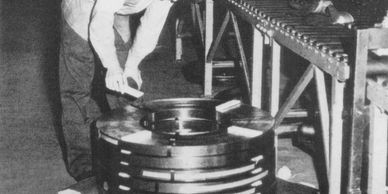

6. Narrow width coils are slit to order

Precise slitting tolerance and proper care in packing insure a good clean slit edge on all light gauge orders produced on our CMP slitter. Your order can be produced on any of six coil IDs, 5.5, 8, 10, 12, 14, 16 inches.

7. Normal coil packing

Our standard packing has wood or cardboard separators placed between each coil. Upon special request, cardboard can be placed under each band on every coil or each coil can be individually paper wrapped. All skids are then shrouded with plastic to protect the metal from dirt and moisture.

Copyright © 2019 Mokes Steel, Inc. - All Rights Reserved.